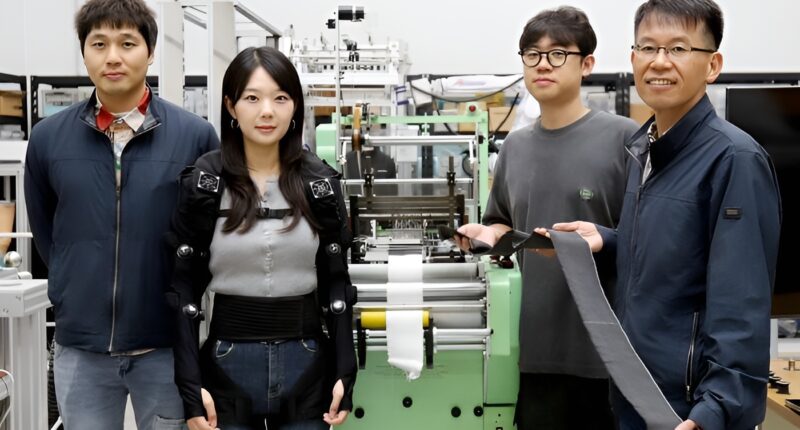

A new automated weaving system has solved a key manufacturing bottleneck for wearable robotics, enabling the continuous mass production of “fabric muscle” for the first time. This breakthrough, developed by the Korea Institute of Machinery and Materials (KIMM), clears the path for commercialising lightweight, powerful actuators for the healthcare, logistics, and construction sectors.

The system weaves shape memory alloy (SMA) wire, just 25 μm in diameter, into a coil-shaped yarn. The resulting fabric actuator is extremely lightweight at only 10 g, yet it is powerful enough to lift 10–15 kg. KIMM’s team achieved automated production by redesigning the yarn to use a natural fibre core instead of a metal one, which had previously hindered the weaving process.

This development directly addresses the primary limitations of conventional wearable robots, which rely on heavy, bulky, and noisy motor or pneumatic actuators that restrict support to single joints.

Multi-joint wearable robots

KIMM’s fabric muscle enables the production of multi-joint wearable robots. The team has developed the world’s first clothing-type robot, weighing less than 2 kg, that simultaneously assists the elbow, shoulder, and waist. This device was proven to reduce muscle effort by more than 40% during repetitive physical tasks.

For the healthcare market, an ultra-lightweight 840 g shoulder-assist robot was developed for patients with muscle weakness. Clinical trials at Seoul National University Hospital (SNUH) found the device improved the shoulder movement range of patients by more than 57%.

“Our development of continuous mass-production technology for fabric muscle—the key component of clothing-type wearable robots—will significantly improve quality of life in fields such as healthcare, logistics, and construction,” said Dr. Cheol Hoon Park, Principal Researcher at KIMM’s Advanced Robotics Research Centre. “We will continue to build on KIMM’s extensive wearable robotics technologies to accelerate commercialisation and lead the global wearable robotics market”.